Improvement of processes in the railway sector

Design and implementation of an automated train wheel painting process (including the pre-treatment process).

![]() INNOMAT Engineering

INNOMAT Engineering

Design and implementation of an automated train wheel painting process (including the pre-treatment process).

Selective enameling process for anodised aluminum by means of the use of latest generation inks cured with unique technology in Europe.

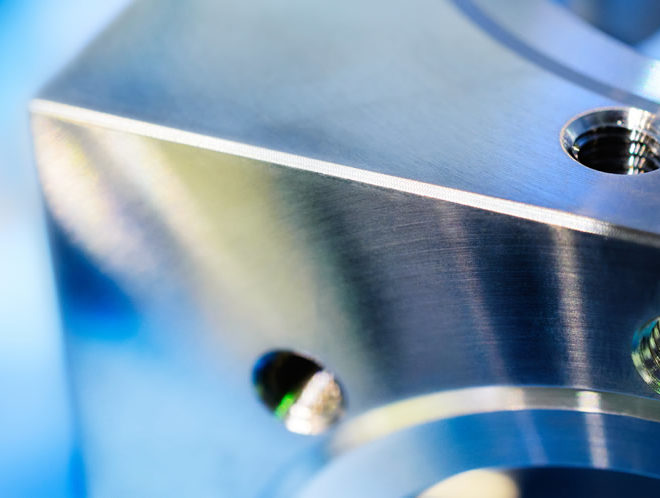

Optimisation and industrial development of the electrolytic plasma treatment ALODINE EC2. The first European line for Alodine EC2 treatment was installed at INNOMAT in collaboration with the multinational Henkel.

Anodizing and painting treatments for magnesium.

Design, development, implementation and automation of painting and surface treatment facilities.

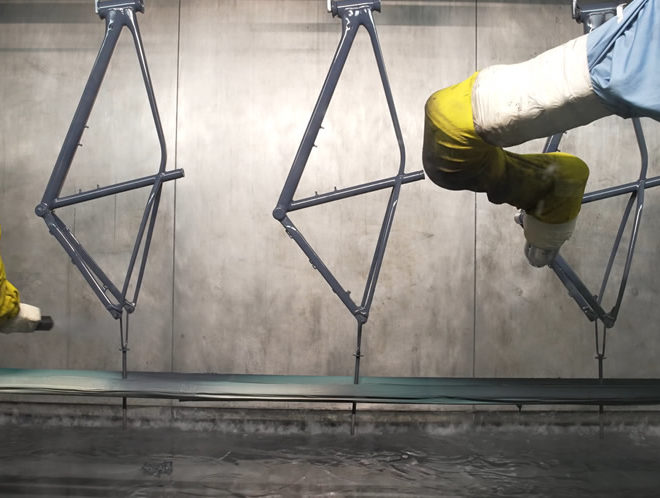

Development, start-up and ongoing support for the industrial implementation of manual and automatic installations for painting bicycle frames.

Engineering of plastic/metal injection processes (extrusion, injection, blowing, stamping…).

Integrated product management. Ad-hoc product development:

Development of a paint for application on wind turbine blades for the onshore/offshore wind industry.

New aesthetics and colours. Customized paints.

Development and industrial implementation of an alternative primer (soft black) to chromic conversion layers for the automotive sector.

![]() WhatsApp

WhatsApp